“Up until a few years ago, there wasn’t anything available for less than $40,000”

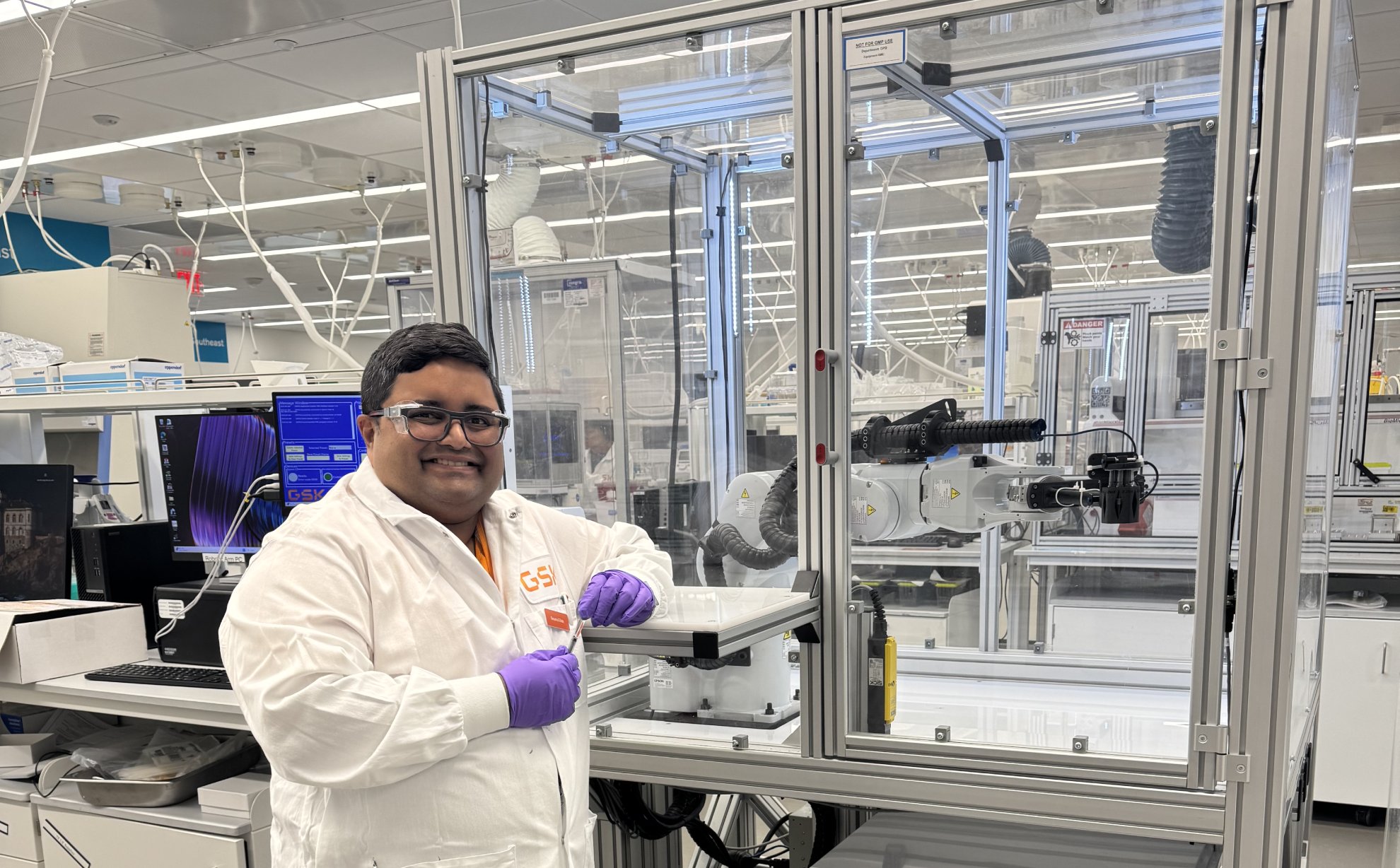

Ekramul Haque Ehite, Ph.D.

GSK – Collegeville, Pennsylvania, USA

RBTX Facts

Less cost

Below $40,000

Less complexity

Plug-and-program setup

Less time

Rapid deployment via RBTX

Less risk

Proven concept with manual testing

In a nutshell

When GSK needed a solution to automate the physically demanding and inconsistent process of vial shaking in pharmaceutical labs, they turned to RBTX and Industrial Robot Help (IRH). The challenge: replicate manual shaking forces of up to 20 Gs – four times the acceleration experienced by Formula 1 drivers. Through creative engineering, manual testing, and robotic innovation, the team developed a low-cost, high-performance system using an Epson C8 robot and custom 3D-printed tooling. The result is a flexible, precise, and scalable automation solution that improves data consistency and relieves lab personnel – all while staying budget-friendly.

The challenges: extreme acceleration and precise motion control

GSK is a global pharmaceutical company that needed a unique automation solution for its laboratory environment. The task: automate the shaking of vials to mix sediment and liquid after long storage – a process previously done manually with high physical strain and inconsistent results.

Precision meets performance – and every movement counts:

The automation system had to replicate human shaking motions with extreme acceleration and flexibility. The robot’s tasks were demanding and highly specialized:

- Shaking pharmaceutical vials with up to 20 Gs of force

- Mimicking human arm motion using a compliant extension

- Handling various container types with custom 3D-printed tooling

- Providing adjustable motion profiles via HMI software

Efficiency meets affordability

The decision to use the Epson C8 robot and RBTX components was driven by the need for a cost-effective solution. The entire system was implemented for under $40,000 – a fraction of the cost of conventional lab automation. Thanks to modular hardware and in-house development, the solution was quickly deployed and tailored to GSK’s needs.

Tailored innovation instead of off-the-shelf robotics

Together with IRH and RBTX, a custom solution was developed that combines creative engineering with low-cost automation. From manual testing to robotic precision, the project showcases how flexibility, persistence, and smart design can solve even the most extreme automation challenges.

The solution: Automated vial shaking with precision and adaptability

To reduce physical strain on lab personnel and improve consistency in pharmaceutical testing, an automated vial-shaking system was developed. At the heart of the solution is an Epson C8 robot, enhanced with a compliant extension arm to replicate human shaking motion.

Capable of generating accelerations over 20 Gs, the robot mimics wrist, elbow, and shoulder movements with high repeatability. Custom 3D-printed end-of-arm tooling allows for flexible handling of various vial types, while a specialized HMI software enables precise control over motion parameters.

The system eliminates manual shaking entirely, improving ergonomics and ensuring reproducible results across all samples. Adjustable settings allow quick adaptation to different testing protocols, minimizing downtime and maximizing efficiency.

Thanks to low-cost components and in-house development, the solution was implemented for under $40,000 – making it ideal for research environments with high demands and limited budgets.

Key facts

Robot Model

Epson C8

Acceleration Achieved

>20 Gs

Custom Features

3D-printed EOAT & customizable HMI software for motion control

Cost Efficiency

Total solution under $40,000

Conclusion

Automation in pharmaceutical labs is more than just a technical upgrade – it transforms how routine tasks are approached. The vial-shaking solution developed for GSK shows how targeted innovation can replace repetitive manual work with a system that delivers consistent results and reduces physical strain.

The choice to pursue this custom solution was strategic: moving away from manual variability and toward reliable, programmable automation. The result is a more resilient lab setup that maintains performance even under staffing constraints – and a team that can focus on research and development.